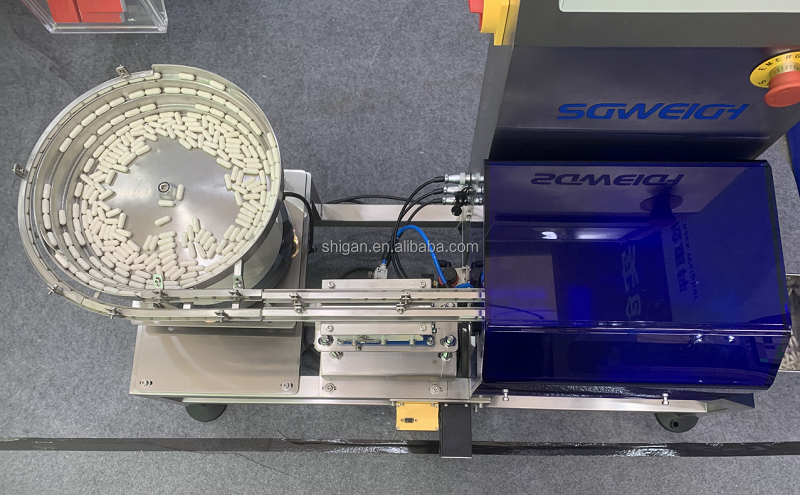

In the capsule filling workshop,the operator or the feeding machine regularly takes a certain number of capsules from the discharge outlet of the filling machine,then pours them into the vibratory feeding tray of the 1/2 Lane Automatic Weighing Capsule/Tablet Sampling Check Weigher.The feeding tray makes all the capsules in the tray line up and move them to the weighing unit one by one.

The weighing unit checks the filling of each capsule by weighing the weight of the capsules at high speed,and the rejection unit automatically rejects the unqualified capsules which exceed the quanlified weight range.

Type: SG-DJ10

Weighing range: 20-2000mg

Sorting accuracy: ±0.1mg (Depends on products)

Graduation value: 0.1mg

Single lane speed: 100pcs/min

Power supply:AC220V±10%50HZ

Power:about 100W

Weight of machine:about 80kg

Main material:SUS304(Stainless Steel)

For reference only, please consult for details !

Contact us to recommend a product that is suitable for you !

◎It is mainly used for sampling of capsules/tablets,regular or irregular small batch weight detection.

◎It can be directly connected to the capsule filler/tablet press,or it can also be used in a single machine.

◎There is no need to change the mold,and it is suitable for capsules or tablets of various sizes.

◎Automatic recycling of qualified products.

◎All capsule channels are open structures and the capsules move smoothly.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Checkweigher and Metal Detector Combo

Food Metal Detector

Industrial Metal Detector

Pharmaceutical Metal Detector

Vertical Metal Detector