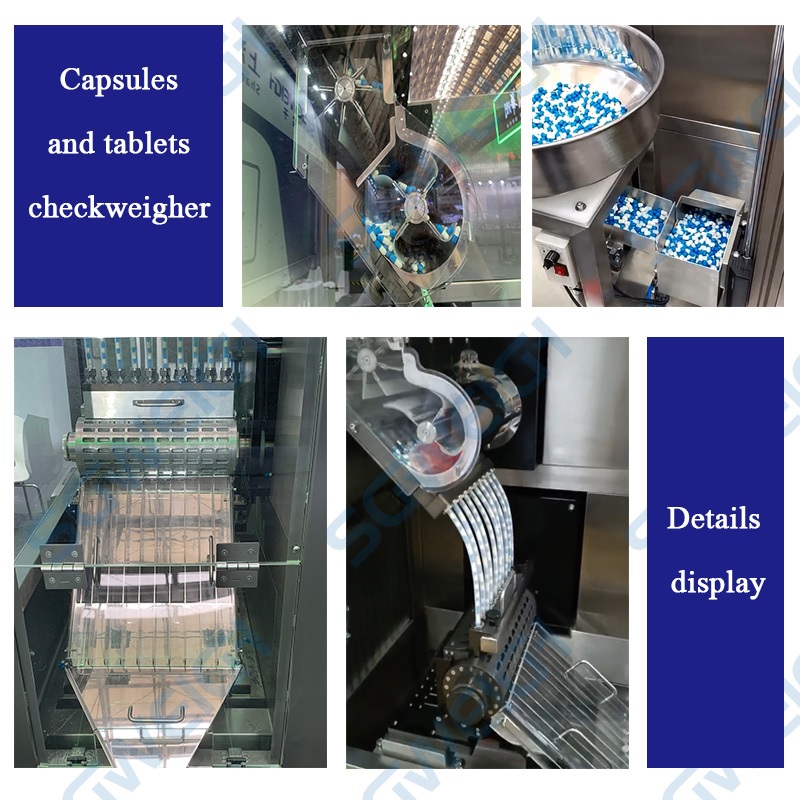

The 24-Lane 000#-5# Capsule Checkweigher is an ultra-high-speed, multi-channel online weighing device designed for high-precision weight detection of small capsule products. The Capsule Checkweigher with Lifting Mechanism and Reject System employs a 24-channel parallel structure, enabling simultaneous independent weighing and judgment of 24 columns of capsules, significantly improving detection efficiency and making it particularly suitable for high-speed filling and multi-column packaging production lines.

Type:SG-JN24

Weighing scope:5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability:200,000-240,000 PCS/HR

Number of columns:24 Columns

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Humidity:30-70%(but no condensation)

Shell material:SUS304

You can choose the most suitable number of channels based on your production volume.

1. 24-Channel Synchronous High-Speed Weighing

24 independent detection channels, a single unit can meet high-volume production needs.

2. High-Precision Weighing System

Suitable for detecting micro-weight capsules, with strong stability and high repeatability.

3. Automatic Defect Rejection

Real-time separation of underweight and overweight capsules, improving the pass rate.

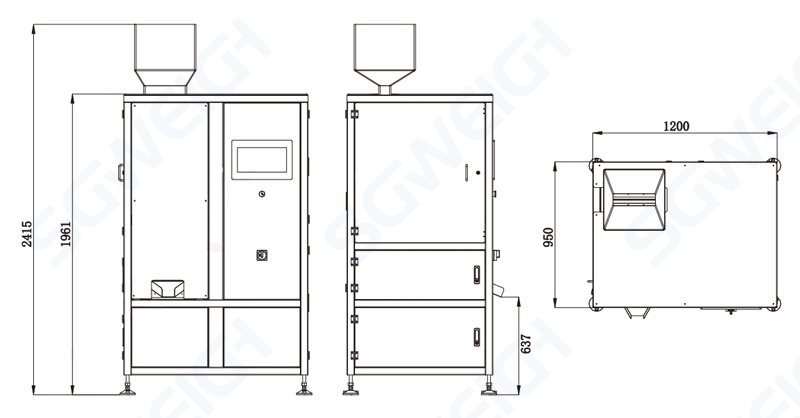

4. Compact Structural Design

Saving production line space and easy integration with existing equipment.

5. Intelligent Touchscreen Control

Integrated formula storage, data statistics, and alarm prompts.

6. Supports Complete Line Integration

Can be integrated with metal detectors, packaging machines, etc., to form a complete quality inspection solution.

Powder-filled capsules

Granular-filled capsules

Nutritional supplement capsules

Health product capsules

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.