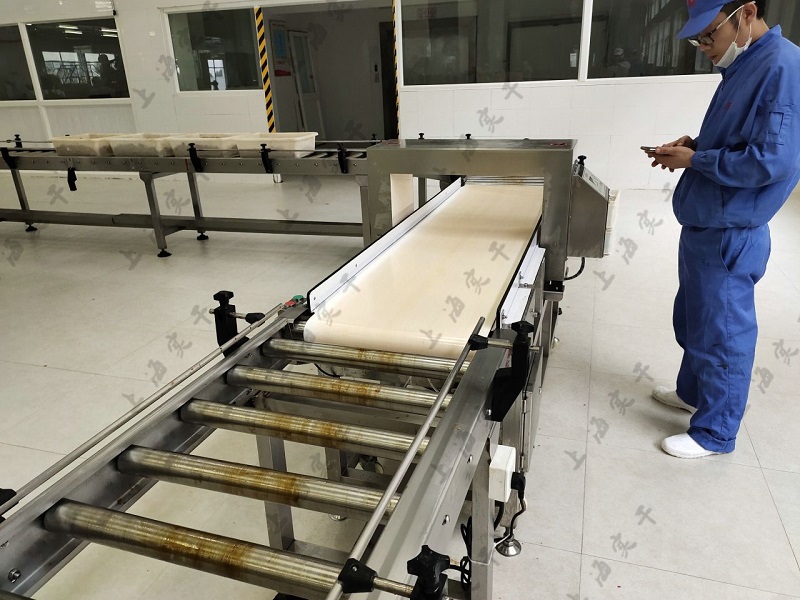

The Heavy Object Conveyor Industrial Metal Detector is designed for online detection of heavy, large-sized metal foreign objects, suitable for heavy

products such as cartons,bulk food packages, and chemical raw materials.

This Automatic Metal Detector features a wide, high-access design, accommodating oversized objects while maintaining high detection stability.

Its modular frame structure ensures strength, durability, and easy maintenance.

Type:SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input/Touchscreen

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

1. Automatic Metal Foreign Object Detection: Real-time identification of various metal contaminants, including ferrous, non-ferrous, and stainless steel.

2. Heavy Material Support: Suitable for heavy, large-volume bags, pouches, drums, or full cases of products.

3. High-Sensitivity Probe: Maintains high detection accuracy even with a large channel.

4. Wide Channel Design: Channel width and height can be customized to product dimensions.

5. Adjustable Conveyor Speed: Adaptable to different packaging lines and medium-speed and high-speed conveyor systems.

6. Durable Stainless Steel Construction: Waterproof and dustproof options available, suitable for humid environments or harsh industrial conditions.

7. System Self-Check Function: Regular self-calibration ensures stable and reliable detection performance.

8. Production Line Integration: Supports external communication interfaces for integration with packaging machines, conveyor lines, and weighing systems.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.