Check Weight Machine With Barcode Label Printer's flexible label handling improves production line efficiency.The combination of dynamic weighing and high-speed labeling machine.It uses a color touch screen. The real-time printing and labeling technology that integrates thermal transfer printing and automatic labeling has the advantages of high performance and low cost.Wide Conveyor High Speed Weigh Price Labeller is widely used in various automated production lines and logistics links to realize automatic printing and printing of real-time information.Welcome to consult for quotation information!

Labeling speed: 70-90 pieces/minute

Display: 12 inch touch screen

Label size: small 20mm*20mm large 120mm*120mm

Customizable (any)

Body material: all stainless steel

Weighing range: 1500g/3000g/6000g

Weighing accuracy: e=0.5g/e=1g/e=2g

Weighing and labeling speed: up to 70 pieces/minute

Labeling method: Pneumatic stamping / blowing

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. The labeling machine is durable: the moving guide rod of the labeling head adopts double rods and ball bearings, so it ensures the high precision of labeling and the durability of the labeling machine.

2. Suitable for barcode printing and labeling of products of different heights: through the automatic induction adjustment control of the cylinder stroke, the sato labeling machine can easily automatically label products of different heights. It can be attached to the bottom, side, and arc surface. The load cell adopts German HBM.

3. Easy to adjust: Adjust the gap between the labeling head and the edge of the label through four screw adjustments, and use the TEST mode to adjust with one key on the keyboard to optimize the entire printing and labeling process.

4. Pre-labeling key: This key can test the labeling process, press the key once, the label will be printed and adsorbed on the labeling head, and then press the key again to label.

5. Compressed air unit: installed next to the printer, by adjusting the valve to ensure the quality of labeling, the flow rate is less than 2CFM.

6. High flexibility: the labeling method can be selected according to the characteristics of the product. Blowing labeling can label circular and irregular products.

7. Strong real-time performance: Barcode sticky notes, the content can be printed immediately from the company's ERP system and weighing system.

8. Open signal transmission system: USB keyboard and barcode scanner can be connected

9. Label paper quality can be selected according to requirements.

Our products can be shipped by sea,air and land.

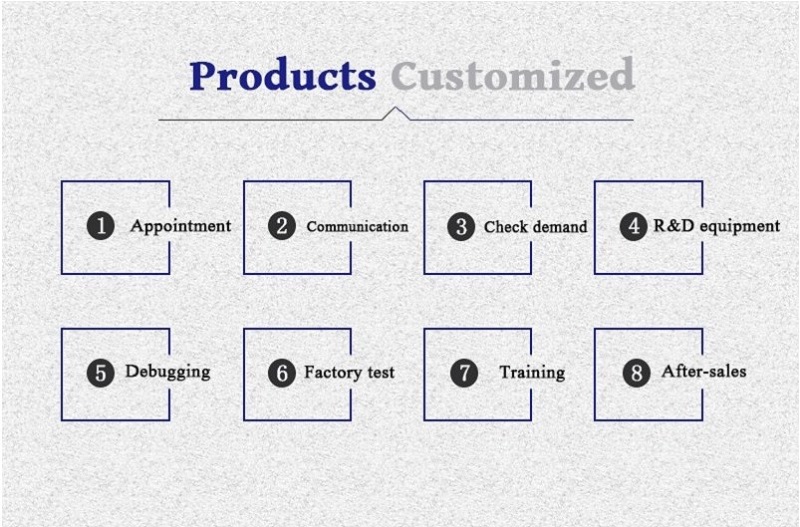

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.

Industrial Checkweigher

Pharmaceutical Checkweigher

Capsule Check Weight Machine

Rotary Check Weigher

Multi-Lane Check Weigher

Weight Labeling Machine

Multi-Level Weight Sorting Machine