High Capacity Automatic Heavy Boxes Checkweighers are online dynamic weighing devices specifically designed for large, heavy products (such as 25-50kg bags, cartons, or drums). They act as the "last line of defense" in the packaging line, ensuring that every product leaving the warehouse meets weight specifications.

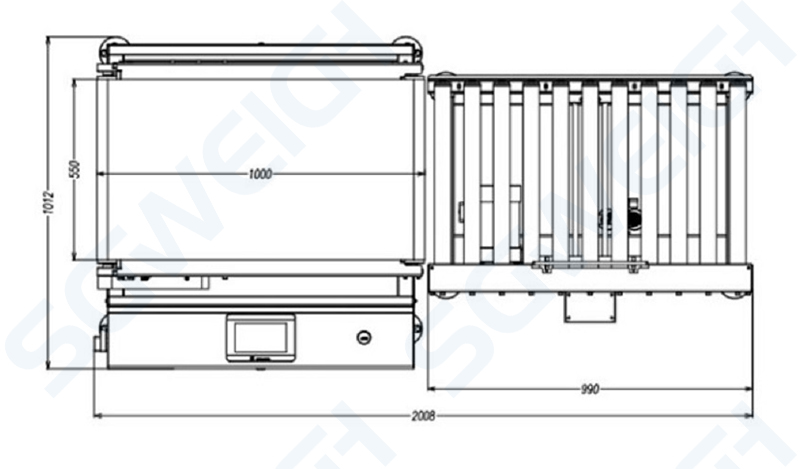

Type :SG-600

Weighing Range :0.5-50Kg

Limited of product: L: 800 W:600 H: 3-400mm

Accuracy:±20g Depends on product

Division Scale:1g

Belt Speed :0- 40 m/min

Max Speed :30 pcs/min

Belt Width :600mm

Machine Weight :80+50kg

Power Supply :AC 110/220V ±10% 50HZ

Power :500W

Main Material :SUS304 stainless steel

1. Automatic Rejection Mechanism: Unlike lightweight checkweighers, heavy-duty checkweighers are typically equipped with reinforced pusher and

heavy-duty diverter rejectors to handle the inertia of large items.

2. Data Traceability and Connectivity: Supports Industry 4.0 standards and can interface with host computers, ERP systems, or packaging lines via RS485,

Ethernet, or Profibus to achieve real-time data statistics and report generation.

3. Automatic Zero-Point Tracking: Even with a small amount of dust or debris remaining on the conveyor belt, the system can automatically zero out,

ensuring zero-point stability during long-term operation.

4. Customization: Supports multi-segment weight grading, not only identifying qualified/unqualified products but also classifying products by weight

range.

Chemicals/Building Materials: 25kg/50kg powder packaging bags (e.g., cement, fertilizer, resin).

Grains and Feed: Large bags of grains, flour, or animal feed.

Logistics and Warehousing: Missing item detection for large logistics turnover boxes and appliance cartons.

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.