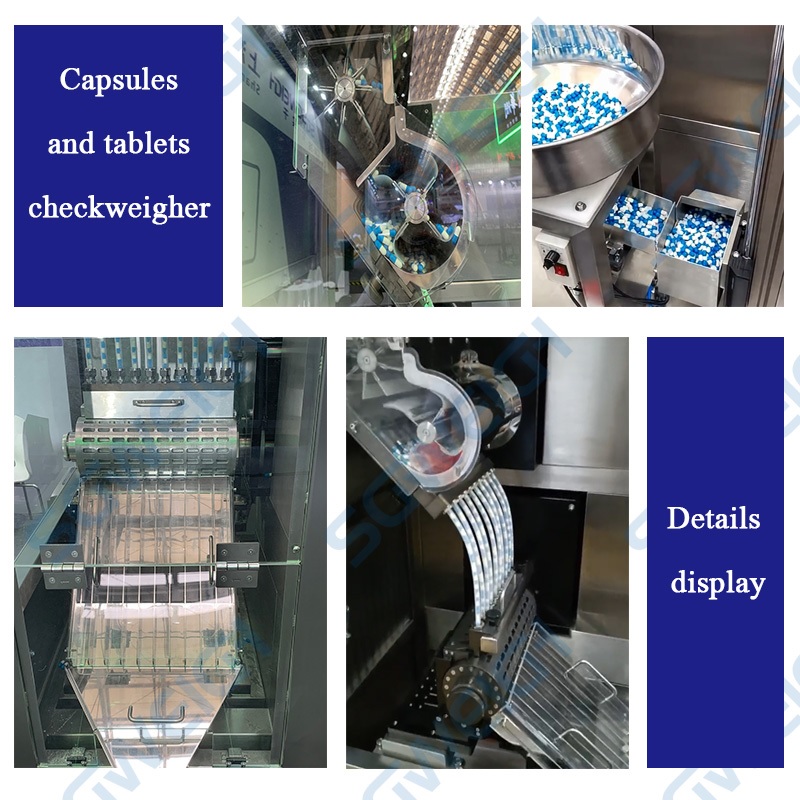

High-Quality 75000 Pcs/Min Capsule Checkweigher can weigh and detect the capsules and tablets, accurate and quickly eliminate unqualified products by weight.Used for off-line weighing in the workshop, especially for capsule filling machine and tablet press machine in the boot debugging stage, final stage (the powder is less), and the grain weight deviation products produced by the instability of filling and tablet pressing equipment in the production process were weighed and detected, eliminate unqualified products, reduce scrape, improve product yield.

Type:SG-JN10

Weighing scope:5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability:75000 PCS/HR

Number of columns:10

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Humidity:30-70%(but no condensation)

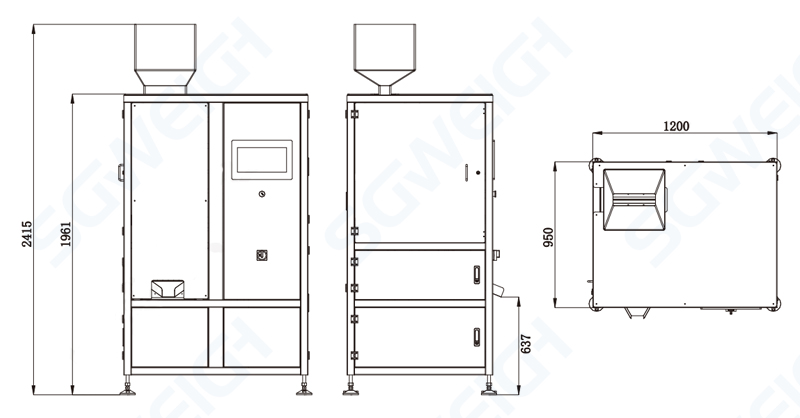

Weight of Machine :350kg

Shell material:SUS304

1. Our unique capsule handling technology eliminates empty capsule bounce and provides a steady feed throughout the inspection process.

2. Every capsule in the system is monitored and tracked.

3. Designed with simplicity and safety in mind.

4. Large intuitive touch screen for quick assessment of production trends.

5. Tool-free replacement parts for capsules size 000 to 5.

6. Protection of the load cell.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.