The Tablet Pharmaceutical Metal Detector is designed specifically for the pharmaceutical industry and is integrated into the back end of tablet presses or capsule filling machines.Capsule Metal Detector accurately identifies and automatically removes metallic impurities such as ferrous, non-ferrous, and stainless steel that may be present in pharmaceuticals, making it a crucial step in ensuring drug safety and achieving GMP certification.

Type:SG-M50

Inlet height: 770-930mm Port size: 76mm

Outlet Height: 770-860mm Port size: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Sensitivity(adjustable or not):Yes

Detection sensitivity: Fe: 0.3mm, SUS: 0.5mm,Non-Fe:0.5mm

Operation Mode:Touch Screen/LED fast key input

Machine weight: 60kg

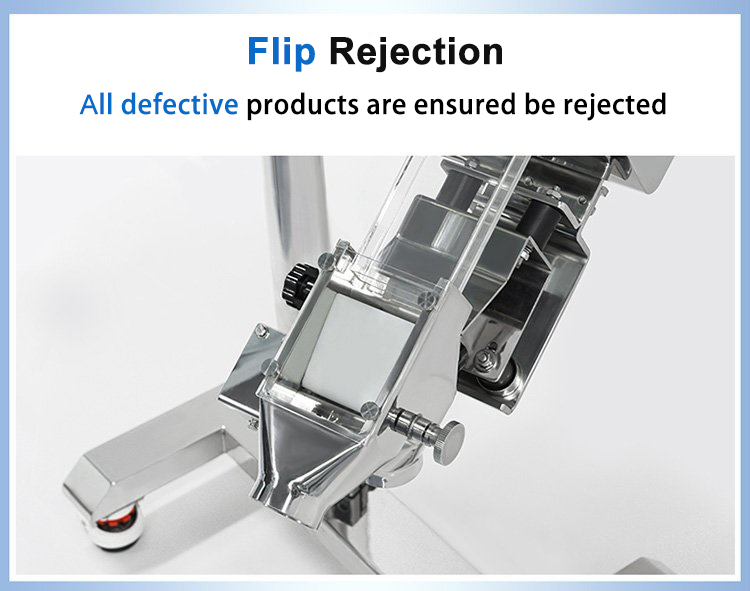

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

1. Extremely high sensitivity: Capable of detecting iron particles as small as 0.3mm in diameter.

2. Compact design: Space-saving, can be directly connected to the tablet press outlet.

3. Automatic rejection system: Employs a flip-plate rejection system to ensure complete separation of qualified and defective products.

4. Easy cleaning: Constructed of 316 stainless steel with a seamless design, meeting pharmaceutical hygiene requirements.

5. Anti-static, food-grade materials for chutes and pipes.

6. Easy assembly and disassembly of parts that come into contact with the product.

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.