The In-Motion High Sensitivity Check Weigher checks the weight of pre-managed products on the production line, automatically rejects underweight and overweight, and prevents defective products from leaving the factory.This equipment is connected with other auxiliary devices to increase inspection efficiency and effectively manage production.Inline Conveyor Auto Check Weigher can be used in many industries such as pharmaceuticals,daily chemicals,light industry,food,chemical industry,hardware,plastics,agricultural and sideline products,etc.

Weighing Range 3-500g

Limited of product L: 200 W: 150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1) Special design and options can ensure long-term operational stability.

2) Single sensor A single sensor is not limited by the area of the weighing platform and can achieve high-speed and high-precision detection requirements.

3) The additional communication module can upload data in real time and monitor effectively.

4) Both large and small objects can be detected.

5) 7-inch or 10-inch color high-definition touch screen, information is clear at a glance.

6) Professional operating system, rich in functions and simple to operate.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

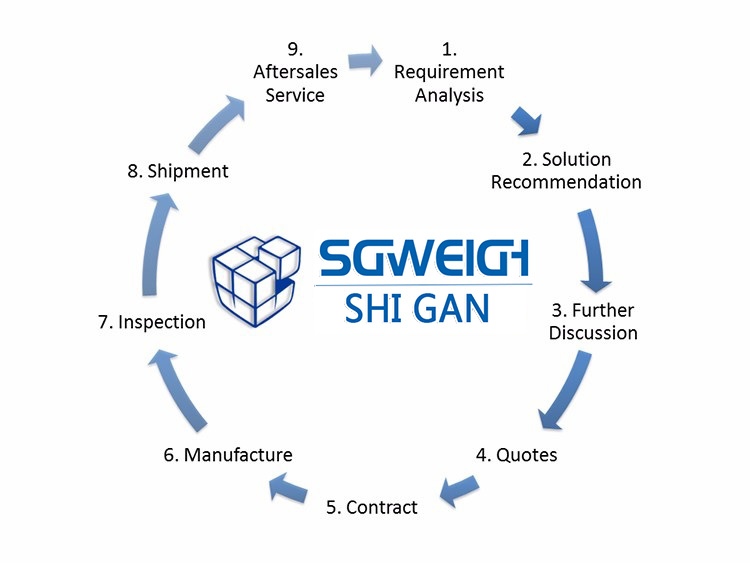

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.