The main differences between large capsule checkweighers and sampling capsule checkweighers are as follows:

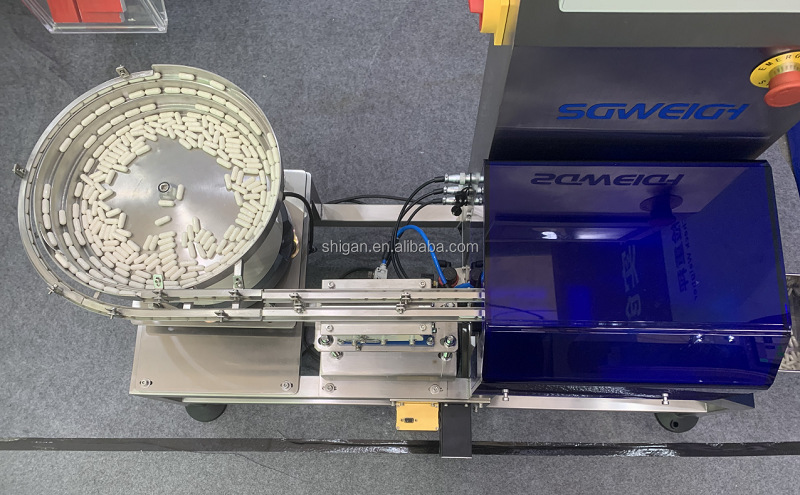

1. Large Capsule Checkweighers

Features:

It is a fully automatic online detection device installed on the production line.

Detect all capsules passing through one by one without missing any.

It has high-speed and high-precision weighing capabilities.

Automatically remove overweight/underweight capsules to ensure 100% product quality.

Applicable scenarios:

Large-scale automated capsule production lines.

Enterprises with strict requirements on the weight of each capsule.

GMP-certified pharmaceutical factories or export companies.

Advantages:

Achieve 100% weight detection and controllable quality.

Can be linked with automatic filling machines and packaging machines to improve overall efficiency.

2. Sampling Capsule Checkweighers

Features:

Automatic feeding in small batches.

Suitable for testing some samples, and can also check the weight one by one, but the speed is slow.

Generally, it is a desktop device with compact structure and low price.

Applicable scenarios:

Laboratory or quality control department.

Production line inspection, batch sampling inspection.

Used to verify whether the filling machine's accuracy is stable.

Advantages:

Low cost and easy operation.

Suitable for small and medium batches or quality control spot checks.

If you are interested in our Capsule Checkweigher,please tell me the specific production requirements, capsule specifications (such as No. 00, No. 0, No. 1, etc.), whether a linkage production line is required, etc., and we will recommend the most suitable model for you.