Food Grade Industrial Metal Detector is a device used to detect metal impurities in the food production process. It can effectively detect metal foreign objects in food, such as nails, screws, etc., thereby ensuring food safety and production efficiency. This kind of detector usually includes a detector head, a control unit, a conveyor belt, and the necessary signal output interface.

Food-grade industrial metal detectors are widely used in various food production fields, such as grain, meat, dairy products, beverages, fruits, vegetables and other industries. In addition, it is also used in chemical raw materials, rubber, plastics, textiles and other industries. In these applications, detectors can detect not only bulk materials but also packaged products.

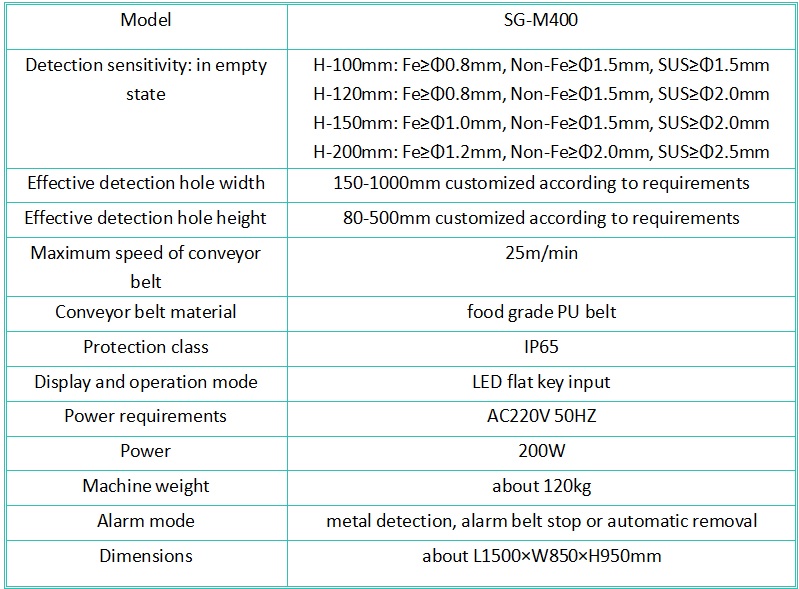

The technical parameters of food-grade industrial metal detectors mainly include:

Sensitivity: The ability to detect metal impurities of different sizes and types.

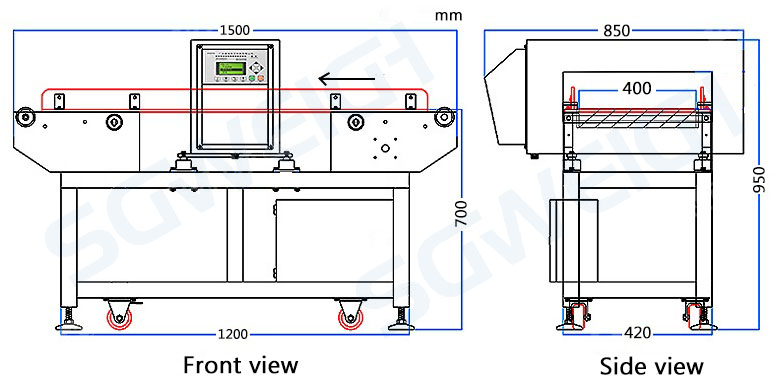

Detection hole size: one of the key parameters that affects detection accuracy.

Working frequency: affects the detection effect of specific metals.

Conveying speed: The speed at which the product passes through the detector affects detection efficiency.

Protection level: reflects the detector's ability to adapt to the environment.

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher

Weigh Labeling Machine