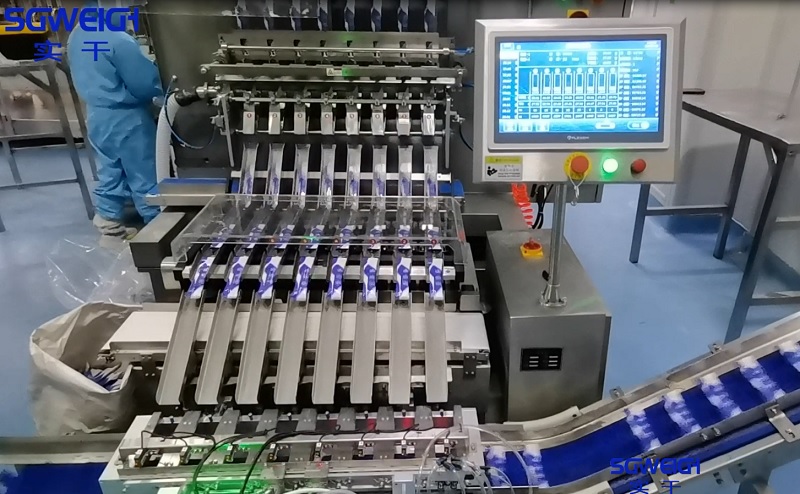

4-10 lane Individual Stick Packs Dynamic Checkweigher can accommodate any high-speed, production-line application requiring precise weighing of small packages.Multi-line Weight Checker for Liquid Sachets Bag offers up to 12 independent lanes, saving space.

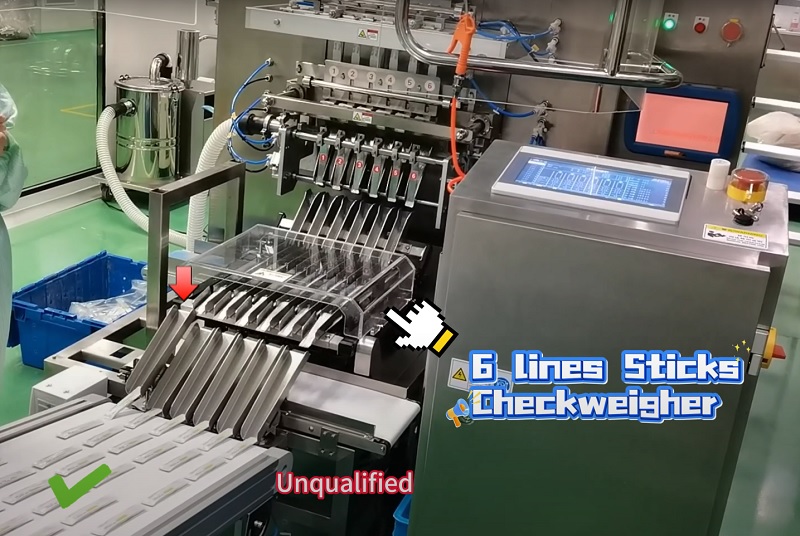

Strip packs are fed from upstream packaging equipment into the checkweigher. An infeed system gently guides the strip packs into 10 parallel lanes. After passing through the weighing area, where weight is checked, qualified packs pass directly through, while unqualified packs are rejected by a reject device.

Type:SG-10X

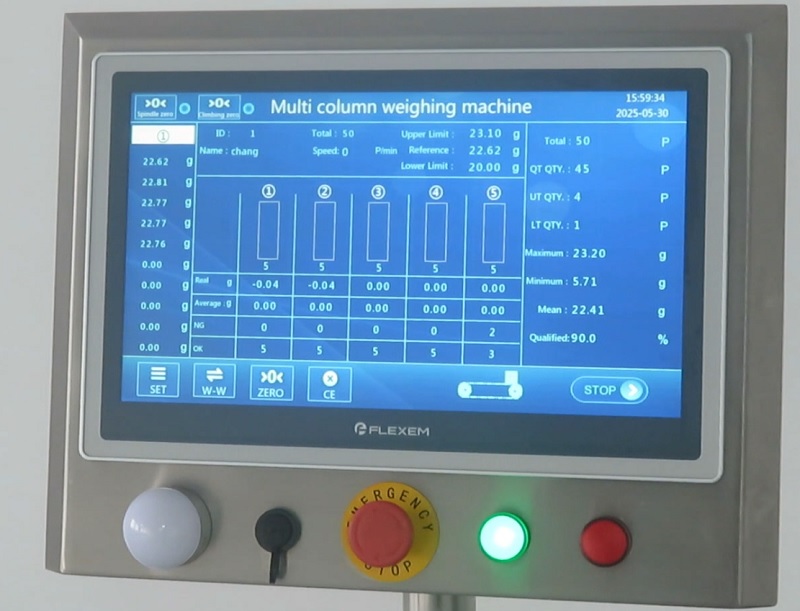

Weighing scope:1-50g

Restrictions of product:L:180 W:40 H:2-20(mm)

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt width:30mm

Highest speed:70pcs/min(one lane) (Depends on products)

Weight of machine:about 200Kg

Powder supply:AC220V 50HZ

Power:about 300W

Main material:SUS304(Stainless Steel)

Multi-channel passing products to improve production efficiency

(the number of channels can be customized)

1.High Speed and Efficiency: Weighing 10 packs at once allows for extremely high production speeds (e.g., thousands of stick packs per hour) without needing a massively long conveyor.

2.100% Quality Control: Every single stick pack is weighed, ensuring no underfilled or overfilled product reaches the consumer.

3.Cost Savings: Prevents "giveaway" (putting too much product in a pack) and identifies underfills that could lead to customer complaints.

4.Process Optimization: The real-time data helps operators quickly identify and correct issues with the filling machines, reducing waste and downtime.

5.Regulatory Compliance: Essential for industries like pharmaceuticals, where strict weight control is mandated by agencies like the FDA.

Pharmaceuticals: Powdered supplements, electrolytes, pain relievers.

Food & Beverage: Instant coffee, sugar, sweeteners, protein powder, drink mixes.

Consumer Goods: Single-use portions of shampoo, conditioner, detergent.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

Q1. Are you a manufacturer or a trader?

A: Shanghai Shigan Industrial Co., Ltd. is a manufacturer located in Shanghai,China. We have our own product design team and factory.

Q2. How many types of checkweighers do you have?

A:Our company has a variety of models of checkweighers, suitable for most products and can be applied to almost all industries. Our company's checkweighers can be customized according to demand.We have standard checkweighers, bottle checkweighers, multi-lane checkweighers,tablet capsule checkweighers, box checkweighers,heavy object checkweighers and so on.

Q3. What factors should be considered when choosing a checkweigher?

What is the product you want to weigh?

How many grams/kg of the product?

What is the size of the product?

What are the speed requirements?

Accuracy requirements?

Based on the above information, our sales will recommend the most suitable checkweigher for you.

Q4. What kind of shipping methods can you provide?

A: Sea, air and international express. We will send photos and videos of the machine to customers before delivery to check the operation of the machine.

Q5. Do you accept customer logos and customizations?

A: We accept all kinds of customization and logos for all products.

Q6. How is the product packaging?Is it easy to be damaged during transportation?

A: No. We use wooden boxes, which are very safe.

TAGS

Automatic Tablets and Capsules Sampling Checkweigher (mg) for Pharma

Dual-Channel Glass/Plastic Bottle Rotary Checkweigher