The Checkweigher & Metal Detector Machine Combination System is characterized by detecting the weight and metal impurities at the same time.One machine is multi-functional,helping food processing enterprises to automatically detect qualified products,unqualified products,missing products,products containing metal impurities,etc.Products, and automatically remove unqualified products to ensure the integrity and quality assurance of ex-factory products.If you are interested in General Purpose Dynamic Combi Metal Detector And Checkweigher,please contact us !

Detection method: electromagnetic induction / digital load cell

Size: 330×150mm

Accuracy: FE0.8mm SUS2.0mm

Sorting accuracy: ±0.5 grams

Weighing range: 5g-900g

Through height: 110mm

Through width: 280mm

Packing length: ≤300mm

Display division value: 0.1g 0.2g 0.5g 1g

Sorting segment number: 3 segments

Sorting capacity: 60 times/min

Conveyor belt speed: 10-45 m/min

Height from the ground: 735mm—800mm

Working temperature: 0-40℃

Weight: about 160 kg

Dimensions: 1900mm×700mm×1120mm (L×W×H)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

★Double-circuit electromagnetic wave detection, the combination of brand-new analog circuit and digital circuit greatly improves the reliability and intelligence of the product.

★It is composed of new touch screen input and large-scale integrated circuit. The CPU completes the collection of analog signals and converts them into digital quantities for processing and output, and automatically retrieves the best point of the metal content of the detected object, greatly improving the sensitivity and reliability of detection .

★ Adopt humanized interface design, the whole operation process is simple and intuitive, the man-machine interface is clear at a glance, and all functions can be directly operated on the screen to complete the executed functions.

★All kinds of required functions and modes can be set, and self-test function can be set.

★ Sensitivity can be adjusted to increase or decrease (90 levels adjustable).

★ When trace metals are detected, the sound, light and instrument will alarm at the same time, and the machine will stop or kick out unqualified products.

★This product uses a computer to form a control system. According to the special requirements of users, it can complete the statistics of the number of detected objects, the classification and statistics of qualified products and unqualified products, data storage and printing, identification of dry and wet concentration products, and mutual interference caused by multiple devices working at the same time. separation and other requirements.

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1. Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2. We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

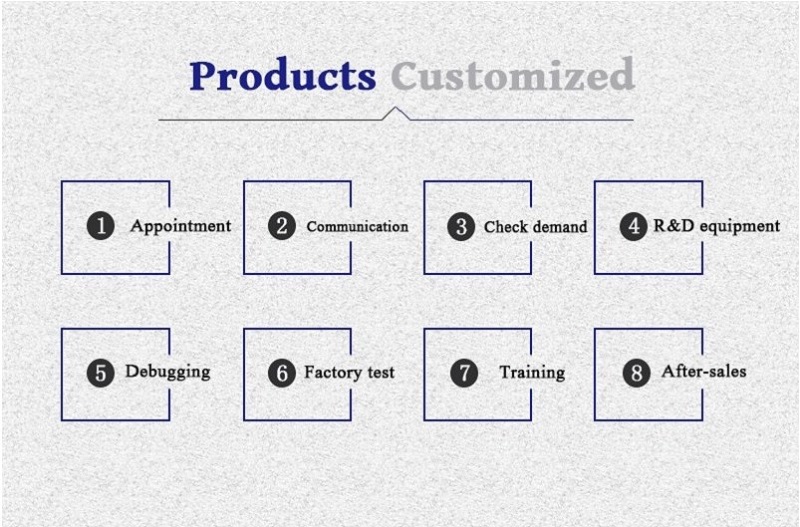

1st step:Customer has showed his special requirements.

2nd step:We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step:Making the conceptive CAD drawing based on communication and understanding.

4th step:Making the detail and 3D drawing agter fixed the design and other details.

5th step:Offer the quotation after confirm the design,material and surface treament.

6th step:Making the sample for approval.

7th step:Testing installation after demo mock up.