The Combined Checkweigher And Metal Detector For Drugs Packaging Industry are integrated together, and at the same time, the weight and missing metal of the product are detected in the last link of the inner packaging, which greatly improves the safety and reliability of production and effectively saves production space.Checkweigher & Metal Detector For Processing Industry can be widely used in food,pharmaceutical,chemical,textile,clothing,toys,rubber and other fields to detect the weight and metal after packaging.It is the first choice for HACCP certification in the food industry and GMP certification in the pharmaceutical industry.

Type:SG-JS220

Main material:SUS304

Inspection Width:220mm

Weighing Range:5-1500g

Weighing accuracy:±0.2g(depends on product)

Detection Width:220mm

Inspection height 100-200mm

Max Speed:25m/min

Capacity:10kg/times

Protection Grade:Ip65

Display:LED

Power:AC220V

Alarm way:Alarm,Belt stop

Size:H:2267 W:589 H:1500 mm(depend on final design)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. The movement, main electrical components and conveyor belts are imported, and the circuit control system uses computer-programmed chips to make the machine more accurate, reliable and stable.

2. This metal detector has an automatic control system, which is scientifically manufactured with special magnetic sensitive materials and special technology, so that the detection accuracy of the needle detector is particularly high.

3. This metal detector has the advantages of high detection accuracy and high detection thickness.

4. Automatic detection, automatic induction, stepless adjustment of 0-10 sensitivity. When there is a broken needle, the conveyor belt will automatically stop and return.

5. It also has two alarm modes: sound effect and light.

6. Automatic shutdown and power saving function without detection for 10 minutes.

7. Luxurious appearance, novel style, saving time and electricity, convenient and quick.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

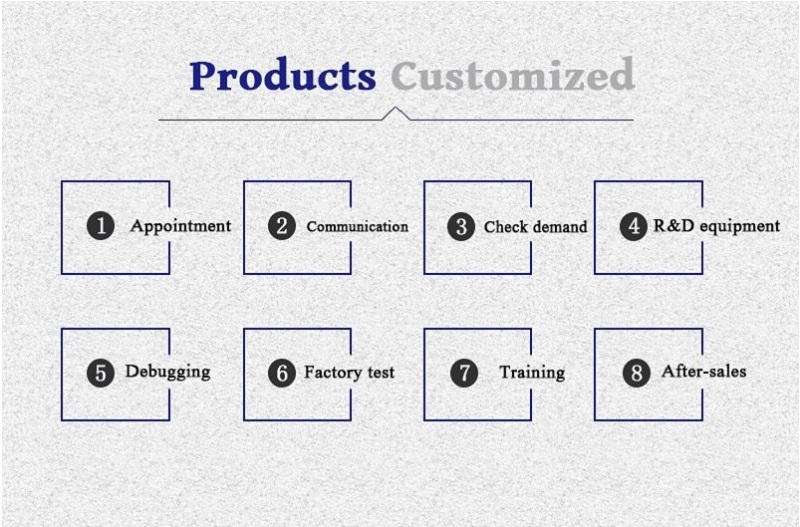

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer's factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.