Conveyor Weight Detector Weight Checkers play a vital role in food manufacturing by ensuring consistency of product weight.Industrial Check Weigher is suitable to check weight of various product, over or less weight will be rejected out,qualify bags will be passed to next equipment.

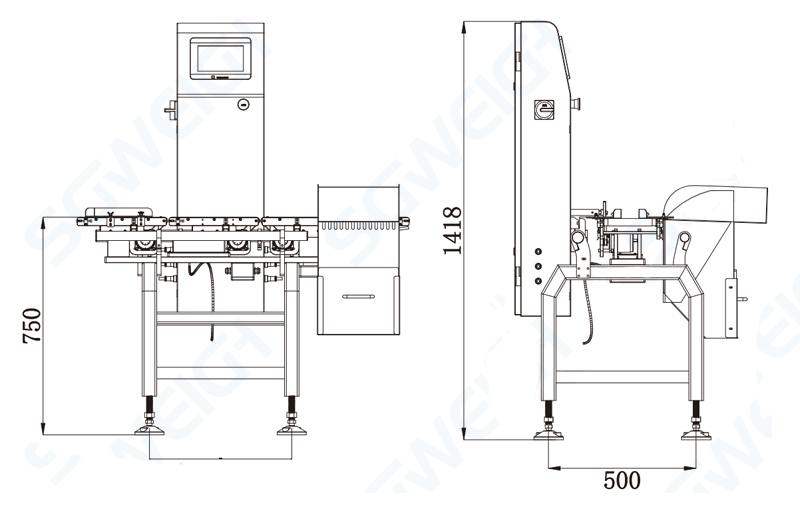

Type:SG-300

Weighing Range:5-3000g

Limited of product:L: 350 W:300 H:3mm or more

Accuracy:±0.3g-0.5g Depends on product

Division Scale:0.1g

Belt Speed:0- 60m/min

Max Speed:80 pcs/min

Belt Width:300mm

Machine Weight:100kg

Power Supply:AC-220V 50HZ

Power:200W

Main Material:SUS304 stainless steel

1.7/10 inch touch screen, easy and friendly operation.

2. Real-time statistical analysis, data can be exported for analysis.

3. Modular structure, easy disassembly and assembly, easy maintenance, stable and reliable.

4. Accurately remove unqualified products, eliminate waste of raw materials, and ensure product quality.

5. Seamlessly connect production lines to improve efficiency.

6.Install emergency switch at the size of machine, user friendly operation.

7.Belt disassembling without tools, which is easier to clean.

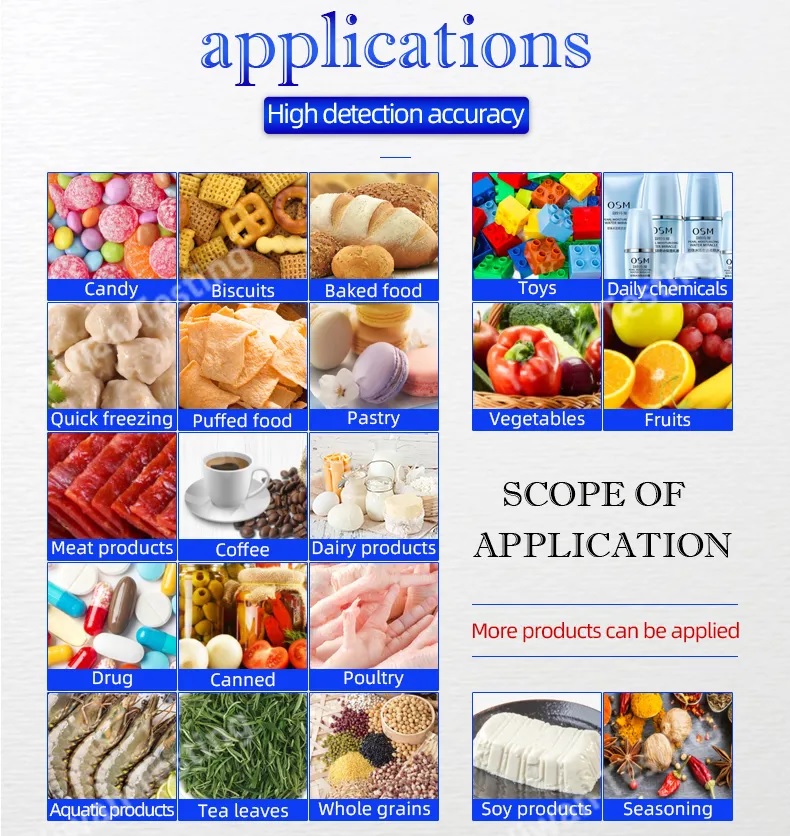

Packaged Food: Testing pre-packaged foods (e.g. snacks, candy, frozen foods).

Meat/Seafood: Sorting meat, fish or poultry products of different weight grades.

Beverage/Dairy: Checking whether the filling volume of bottled water, canned goods, milk and other liquids meets the standards.

Baked Goods: Ensuring the weight consistency of products such as bread and cakes.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

Check Weigher Machine Price,Checkweigher Scale Supplier,Weight Detector