Cosmetic Product Multifunctional Conveyor Check Weigher Combined Metal Detector is a versatile solution for quality control in production lines.It integrates two critical functionalities—weight checking and metal detection—into a single compact system, ensuring that both product weight and contamination standards are met.Checkweigher and Metal Detector Combination Units are commonly used in industries like food processing,pharmaceuticals,cusmetics,andconsumer goods.

Model: SG-JS150

Detection hole width: 150mm

Detection hole height: 100-200mm

Detection sensitivity:

H-100mm: Fe≥Φ0.8mm,SUS≥Φ1.2mm

H-120mm: Fe≥Φ0.8mm,SUS≥Φ1.8mm

H-150mm: Fe≥Φ1.2mm,SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective detection hole width: 150mm

Effective detection hole height: 100-200mm

Weighing range: 5-500g

Weighing accuracy: ±0.1g(Depends on products)

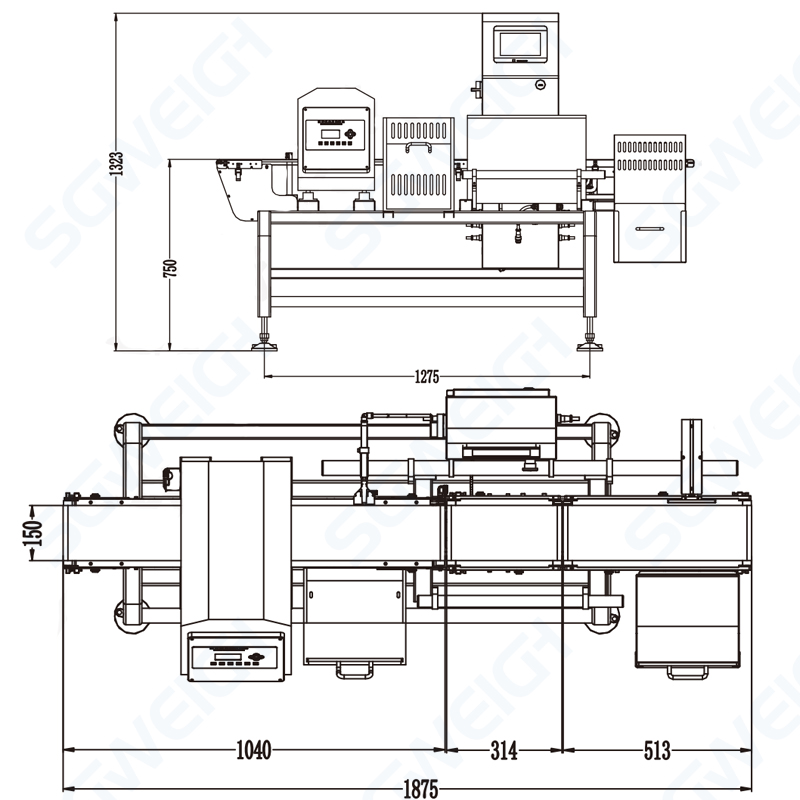

Conveyor belt height: 750mm (±50mm)

Conveying capacity: 10Kg/time

Delivery direction: from left to right

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED LCD flat button input

Machine weight: 240kg

Power requirements: AC220V 50HZ

Power: 300W

Dual Functionality:

Simultaneously checks product weight and detects metal contaminants in one pass, optimizing space and efficiency.

Compact Design:

Saves production floor space by combining two machines into one, making it suitable for facilities with limited space.

High Precision and Accuracy:

Advanced load cells and detection coils ensure accurate weight readings and high sensitivity for metal detection.

Customizable Reject Mechanism:

Options for pneumatic pushers, flippers, or drop-down mechanisms to automatically remove non-compliant products.

User-Friendly Interface:

Touchscreen interface for easy setup, calibration, and monitoring of both weight and contamination parameters.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.