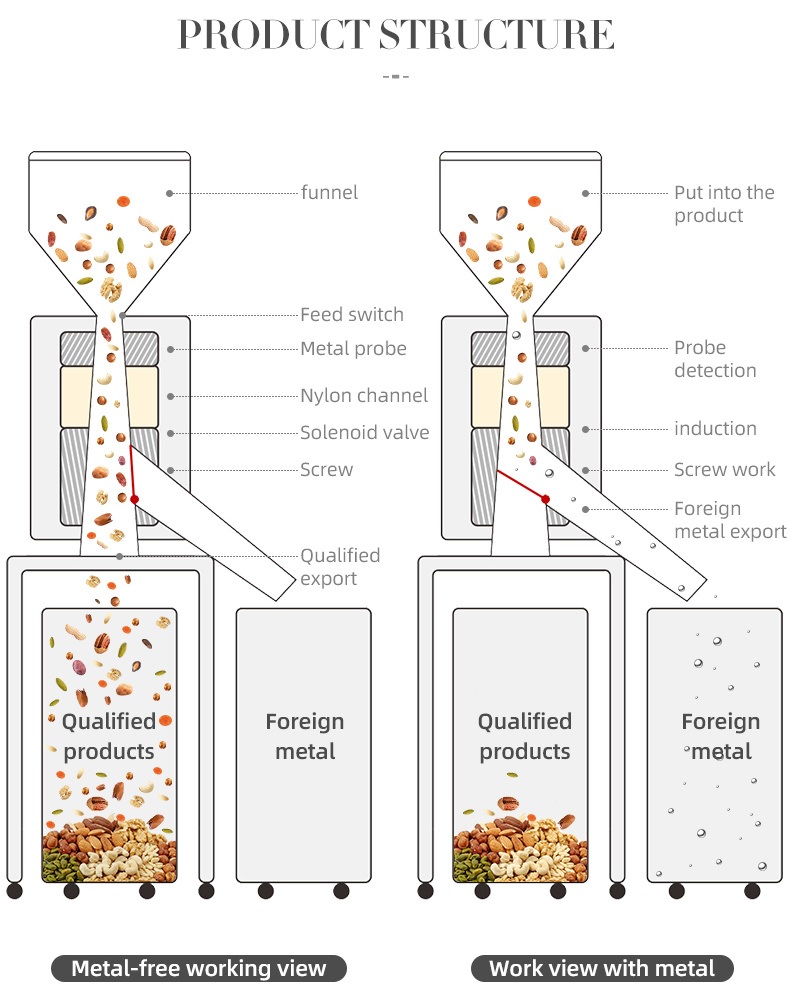

Gravity Throat Metal Detectors are designed to detect metal contamination in continuously flowing free-falling granules or powders. Ideal for inspecting dry, bulk applications including sugar, flour, plastic granules and more.

The Food & Powder Vertical Fall Metal Detection Machine detects even the smallest metal contaminants and the fast-changing separation flap removes them directly from the product flow during production.

Metal detectors are custom-made and can be individually adapted to the requirements of the respective production environment.

Name:Gravity-Fed Metal Detector

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Material of Construction: 304 Brushed stainless steel

Product:Pre-packaged, free-flowing products

Parameter Adjustment:Auto or manual programming

Alarm Model:Auto rejection diversion flap

Machine Weight:60kg

IP Rating:65

1.Low-Profile Design for Tight Spaces

Engineered with a minimal installation height, it’s perfect for gravity-feed lines with limited vertical clearance—ideal for retrofits or compact plant layouts.

2.High-Sensitivity Metal Detection

Using advanced signal processing, it detects ferrous, non-ferrous, and stainless-steel contaminants with exceptional accuracy, even in small particle sizes.

3.Hygienic Stainless-Steel Construction

Built to meet food and pharmaceutical sanitation standards, with smooth, crevice-free surfaces for easy washdown and contamination control.

4.Fast-Acting Auto-Reject

An integrated diverter or flap system quickly removes contaminated products with minimal waste, preserving throughput and line efficiency.

5. Continuous Operation

Designed for continuous operation, it will not affect production efficiency and ensure uninterrupted production.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector