Capsule Metal Detectors are specialized pieces of equipment designed to detect metal contaminants within capsules,a common dosage form in the pharmaceutical industry.These contaminants, such as fragments of machinery, tools, or foreign objects,can pose serious health risks to consumers.

Type:SG-M50

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

1. The above detection accuracy is for reference only. The actual detection accuracy will be obtained after testing.

2. Special specifications can be customized according to customer requirements.

3. The material used for the metal detection device is SUS304, dustproof and waterproof.

4. The sense of detection is related to the properties of the tested product (humidity, temperature, salt content, mineral matter, etc.).

High Sensitivity:

Capsule metal detectors are engineered to detect even small metal particles, ensuring the safety of pharmaceutical products.

Reliability

These devices are designed for continuous operation in demanding production environments.

Efficiency

They can inspect large quantities of capsules quickly, minimizing downtime and maximizing productivity.

Compliance

Capsule metal detectors help pharmaceutical manufacturers meet regulatory requirements and maintain product quality.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Q1. Are you a manufacturer or trader?

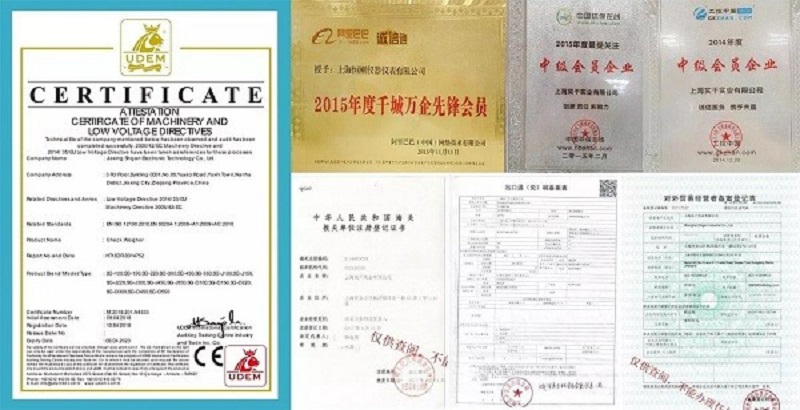

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company's requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

Please let us know the follow details when you need,so that we can check if this model is suitable for your case.Thanks for the consultation!

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?