High Stability Conveyor Belt Metal Detector Machine can detect metal foreign objects. The whole machine design meets the requirements of food machinery and is suitable for connection to assembly line inspection operations.Metal Detector Machine Food Production has high detection sensitivity and good stability. A variety of rejection devices are available to avoid residual metal in products during production.Welcome to consult for quotation information !

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

Dimensions: about L1500×W850×H950mm

1. Phase tracking function to maintain stable high-sensitivity detection capabilities.

2. Product tracking function can automatically adjust and compensate according to changes in product effects.

3. Automatic balance calibration function ensures the service life of the machine.

4. Able to automatically check products, analyze and record.

5. The product database can store 100 products.

6. IP65 dustproof and waterproof.

7. The conveyor belt performance complies with food hygiene standards (FDA) and can be directly used for food inspection.

8. It can work stably for a long time, and the special design is suitable for harsh production environments with strong vibration and high interference.

9. User-friendly interface and easy operation. LCD Monitor.

10. Can be matched with assembly line operations or automatic control devices.

11. Automatic rejection equipment can be installed according to customer requirements.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

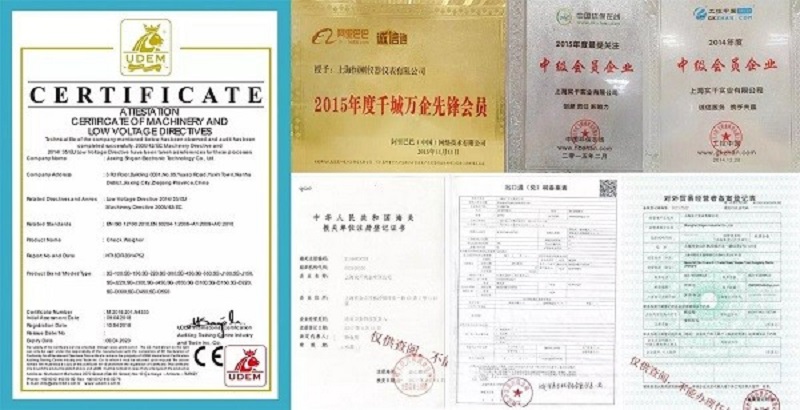

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial Co,.Ltd solemnly promises you with the principles of preferential prices, considerate service and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.