Metallic impurities in your product can always occur, no matter how careful your processes are.Conveyor Metal Detector is critical to remove metal contaminants before they damage production machinery or even the customer. SGWEIGH is pleased to offer several metal detection systems to protect your products.Industrial Metal Detector reliably detects all metal contamination and offers protection against machine damage, production downtime, unhappy customers, and product recalls.

Type:SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

1) Used to detect magnetic and non-magnetic metals.

2) Suitable for bulk and packaged materials.

3) Conveyor systems.

4) Rejection method: Upon detection of a foreign metal object, the belt stops and an alarm sounds, or the object is automatically rejected.

5) A wide range of widths, lengths, and heights are available for flexible selection.

6) Cleanroom design for easy cleaning.

7) Various options are available to meet your needs, standards, and requirements.

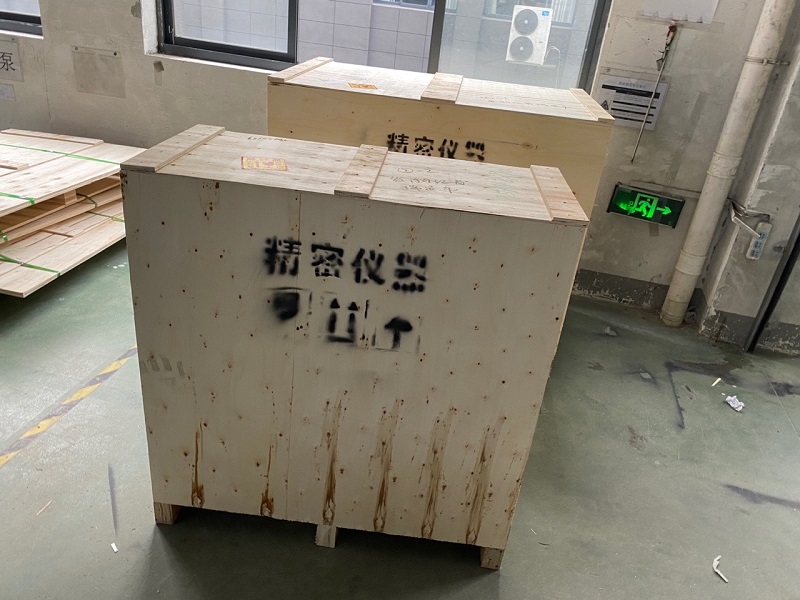

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS