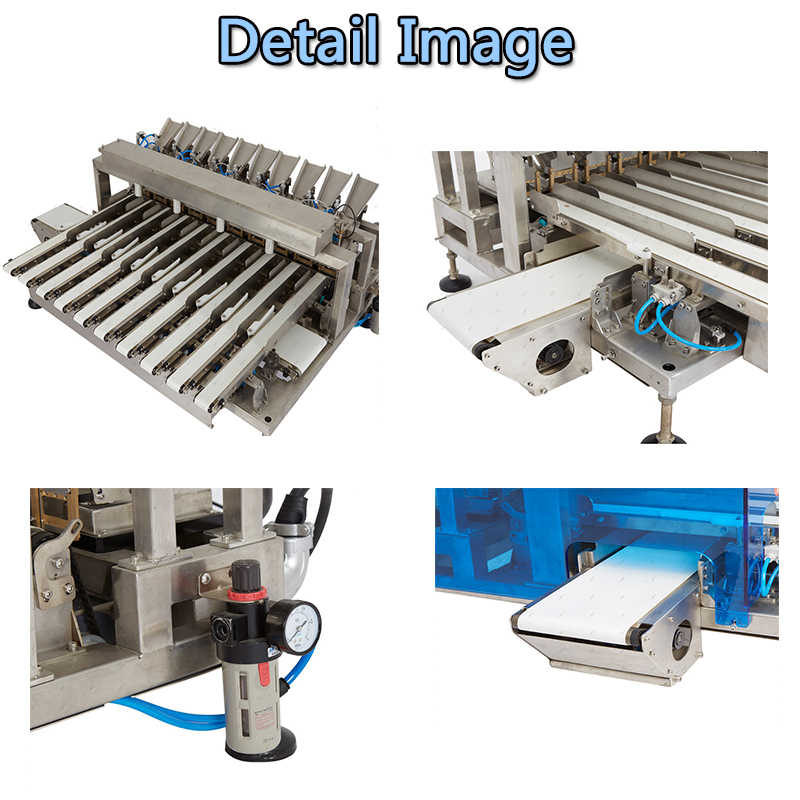

Multi-Lane Inspection With Checkweigher adopts patented weighing structure to realize simultaneous high-precision weighing of each column and independent rejection of each channel. It can perform grain-by-grain check weighing of capsules/tablets.Single Drug Particle Multi-Lane Check Weight Machine can meet almost any production line application that requires high speed.There are many kinds of products,welcome to consult for information and quotation !

Model:SG-Multi-Column Checkweigher

Weighing Range:1-30g

Minimum Scale:0.01g

Sorting Speed:Maximum 50 pieces/min (one channel)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

PowerAbout:1000W

Windshield:Thick acrylic (to avoid airflow interference)

Working Environment:Temperature: 0℃~40℃, Humidity: 30%~95%

Remark:The attributes and usage environments of the tested products are different, and the detection speed and accuracy are also different, and the actual test is used as the standard.

1.Each channel can separately reject unqualified products.

2.The number of continuous unqualified products of each channel can be modified.

3. Statistic data export interface: USB

4.Statistic data of each channel: real time results display, trend graph display, histogram display.

5. Multi-channel data can be counted independently or comprehensively;

6. Check weighing parameters can also be set independently or uniformly;

7. A control module and a display screen;

8. It has the accuracy and speed of multiple single-row checkweighers;

9. Remote real-time monitoring is possible;

10. Space saving and low cost.

1.It is used for automatic weight detection, upper and lower limit discrimination or weight classification and selection on various automatic assembly lines and logistics transportation systems. It can also be used for product packaging and missing parts detection.

2.Widely used in on-line detection in pharmaceutical, food, cosmetic, chemical, hardware and other industries.

3.In addition, it can directly replace manual weighing, so as to protect the customer's brand image and improve the customer's production efficiency and production quality.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.