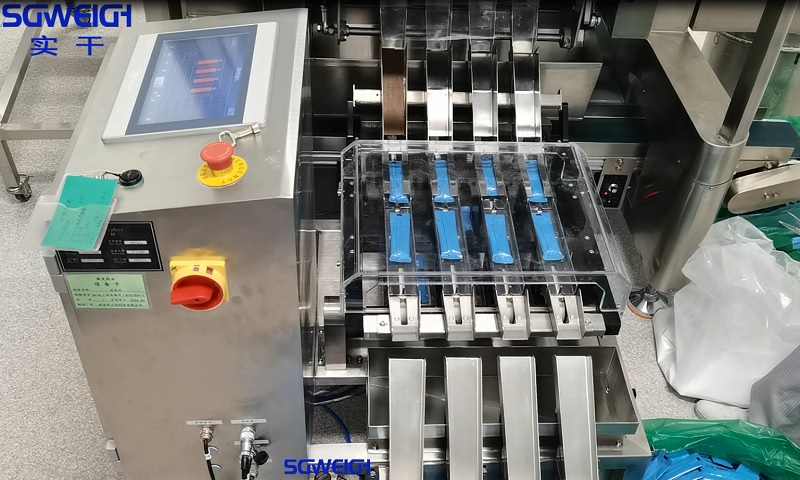

The Multi-Lane Sticks Conveyor Checkweigher is a high-speed online weight detection device designed specifically for liquid and semi-fluid products. It is suitable for multi-row pouch or strip packaging production lines for products such as juices, purees, jams, concentrates, and functional beverages.

The Checkweigher (2-8 lines) can simultaneously and independently weigh and judge multiple packaging channels, achieving 100% online weight detection. This effectively prevents underweight or overweight products from entering the market, helping companies stabilize product filling accuracy, reduce raw material waste, and meet food safety and regulatory requirements.

Model:SG 2-8X

Weighing Range:1-50g

Accuracy: 0.01 gram (depending on the product)

Sorting Speed:40-60 pcs/min (one lane)

Conveying Speed:20-100m/min

Control system: PLC + Touch screen

Conveying Direction:Can be placed according to the actual situation on site

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

1. Multi-column synchronous high-speed checkweighing

Supports 2–12 columns (customizable) for simultaneous checkweighing, perfectly matching multi-column vertical packaging machines or strip packaging machines, significantly improving overall production capacity.

2. Anti-interference design for liquid/purse products

Optimized weighing structure and dynamic algorithm effectively suppress the impact of liquid sloshing and fruit puree flow on weighing accuracy.

3. High-precision dynamic weighing system

Utilizes high-speed weighing sensors and intelligent filtering algorithms to achieve stable and highly repeatable weight detection results.

4. Multi-channel independent judgment and rejection

Each column has an independently set rejection device; abnormal products are automatically rejected.

5. Food-grade hygienic structural design

The entire machine is constructed of stainless steel, meeting food contact requirements and facilitating quick cleaning and maintenance.

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

Automatic Conveyor 1kg-10kg Box Industrial Check Weigher

High-Accuracy Pharma Eye Drop Containers Rotary Checkweigher