Pharmaceutical Metal Detector For Capsule Pill with Flap Rejection is a specialized industrial equipment designed for the pharmaceutical and food industries to ensure the safety and quality of capsules by detecting the presence of metal contaminants.Metal detectors are crucial in these industries to prevent the contamination of products with metal particles, which can be hazardous to consumers and can compromise the integrity of the final product.Welcome to consult for quotation information!

SG-YJ60

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

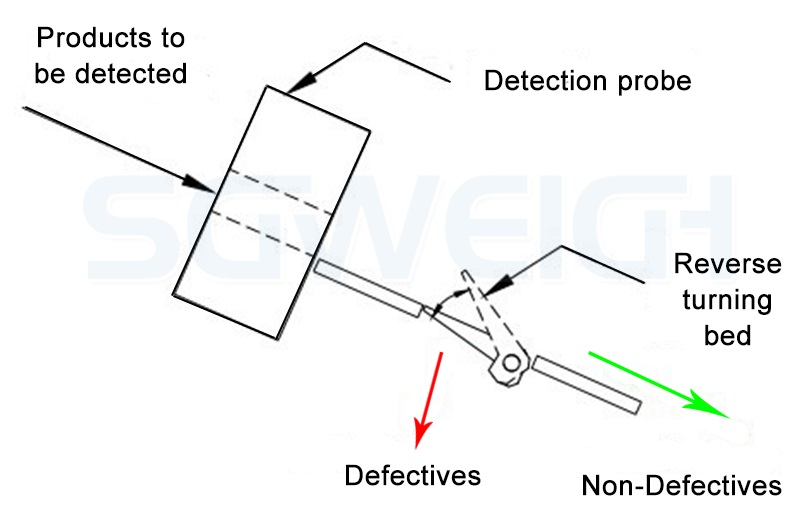

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1.Conveyor System:

Capsules move along a conveyor belt or through a hopper as part of the production line.

2.Metal Detection System:

The machine is equipped with a metal detection system that usually includes a coil or coils through which the capsules pass. These coils generate a magnetic field.

3.Alarm/Rejection Mechanism:

If metal contaminants are detected,, it will trigger a rejection mechanism to divert the contaminated capsules away from the production line.

4.Adjustable Sensitivity:

Capsule metal detector machines often have adjustable sensitivity settings to accommodate different product types and packaging materials.This ensures that the detector can effectively identify even small metal contaminants.

5.Integration with Production Line:

These machines are integrated into the production line, often following capsule filling or packaging processes. Integration ensures that all capsules undergo metal detection before reaching the final packaging stage.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Online Checkweigher

Food Checkwiegher

Large Range Checkweigher

Weight Sorting Machine

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Food Metal Detector

Industrial Metal Detector

Metal Detector Combination Checkweigher