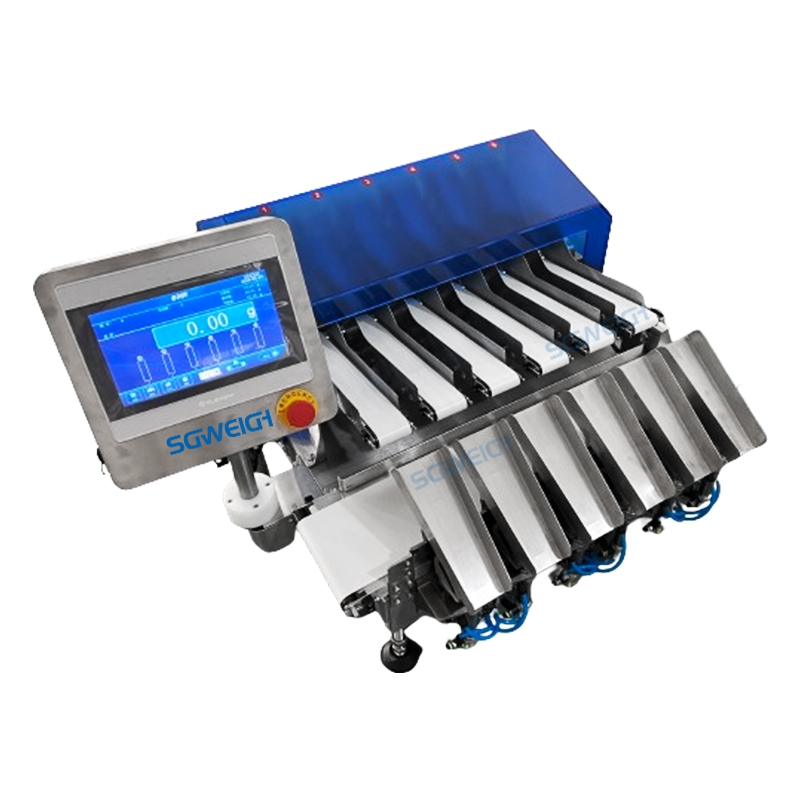

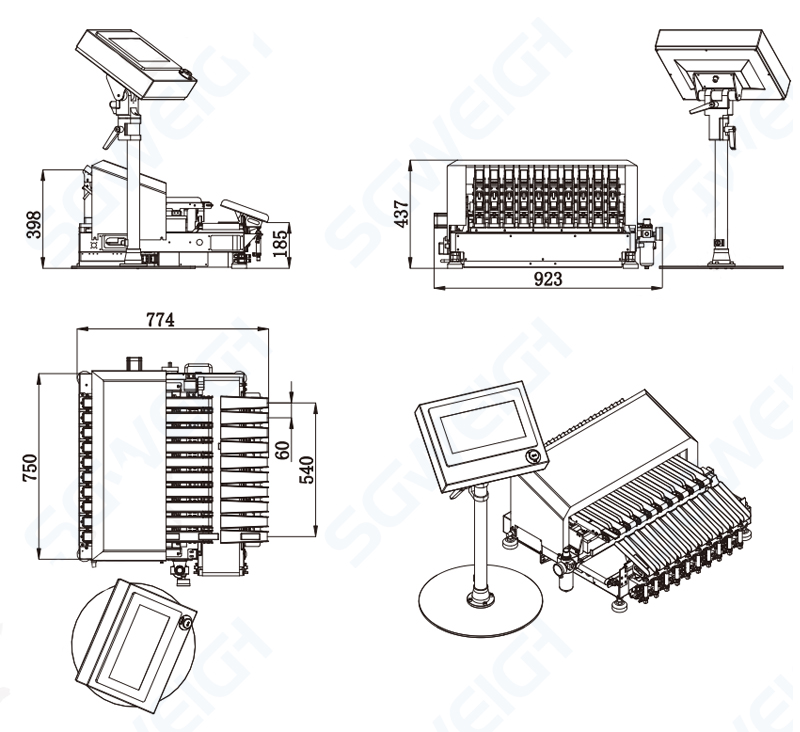

Multi-lane Checkweighers are ideal for nearly any production line application that requires high-speed, accurate weighing of small packaged products.With up to 12 independent lanes, the SGWEIGH offers tremendous productivity in a space-saving form.

Mulit Lane Check Weigher

Model:SG-6X

Weighing Range:1-50g

Minimum Scale:0.01g

Sorting Speed:70pcs/min (one lane)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

Working Environment:Temperature: 0℃~40℃, Humidity: 30%~95%

Efficient, space-saving design:

1. Small footprint, independent channels, trend control.

2. Space-saving design simplifies line integration.

3. No additional spreading conveyor is required, as the checkweigher can receive packages at the same center spacing as the filling and packaging machine.

Independent channels:

1. Each channel can be started and stopped individually.

2. Each channel can be individually configured for different products and weight ranges (optional) for maximum system flexibility.

Easy connection to multi lane filling and packaging machines:

1. The checkweigher controller can be installed near the filling and packaging machine to facilitate adjustment of the filling process.

2. Data output supports common send/receive communication protocols.

3. Each channel's feedback to the filling and packaging machine can be controlled individually to prevent overfilling and increase production.

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company's requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference.Thank you.

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?